Photo Gallery of Rusty Parts

Rust911 Pictures

Framing Square

A very common problem with many automotive trailer hitches. The part was immersed in an ambient temperature RuSt911 Industrial Concentrate and left over lunch break. The parts were rinsed off using Metal Kleener 0001 (no longer available, call for suggestions) and sprayed with Metal shield 2009 to protect from flash rusting. notice how much rust removal occurred. Also, it removed rust from the insides of the trailer hitch tube. Awesome rust remover.

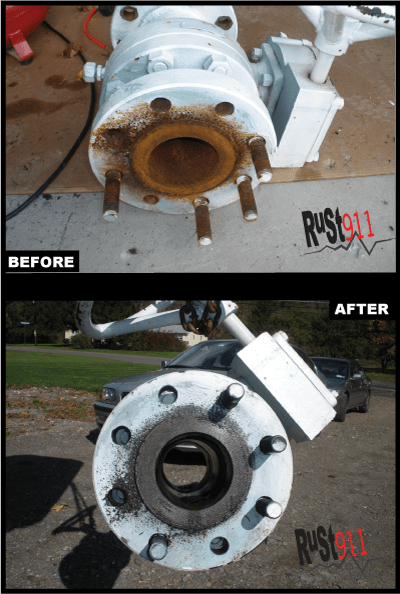

Huge Gas Valve

BEFORE: Customer had a very rusted natural gas valve that was useless to them. the rust was primarily on the insides and on the valve stem. It would cost too much to grind the rust off by hand or abrasive blasting. We lifted the valve up and placed the entire valve into a drum of 10% RuSt911 overnight.

AFTER: Picture shows the valve insides and outsides completely removed of rust. This rust removal project saved the customer hundreds of dollars in new products and labor. Another perfect rust removal application.

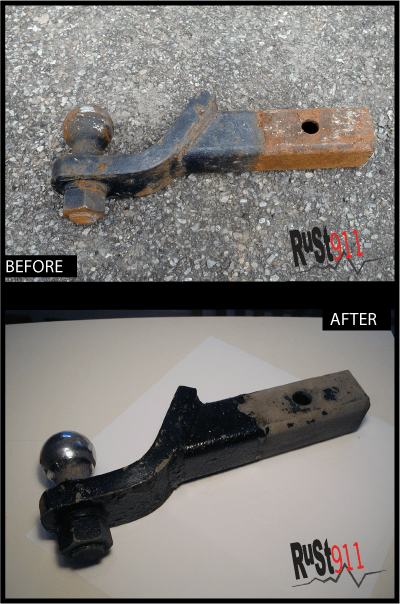

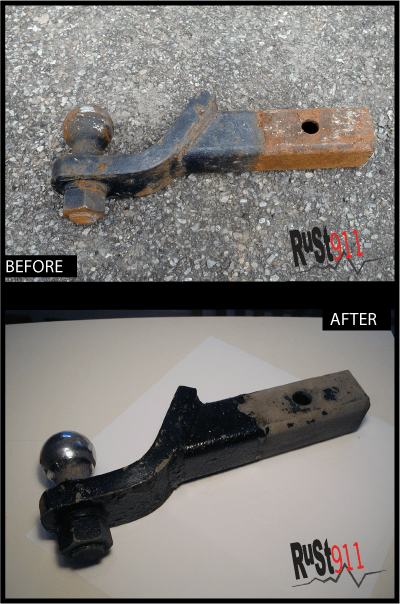

Rusted Trailer Hitch

A very common problem with many automotive trailer hitches. The part was immersed in an ambient temperature RuSt911 Industrial Concentrate and left over lunch break. The parts were rinsed off using Metal Kleener 0001 (no longer available, call for suggestions) and sprayed with Metal shield 2009 to protect from flash rusting. notice how much rust removal occurred. Also, it removed rust from the insides of the trailer hitch tube. Awesome rust remover.

Severely Rusted Wrench

BEFORE: Customer had a very corroded 15" wrench that was left in the back of a contractors truck bed exposed to the rain all summer. The thumb knurl didn't even move.

AFTER: Picture shows half of the severely rusted wrench totally rust free and in perfect working condition. This rust removal job saved the contractor $35 to $45 dollars.

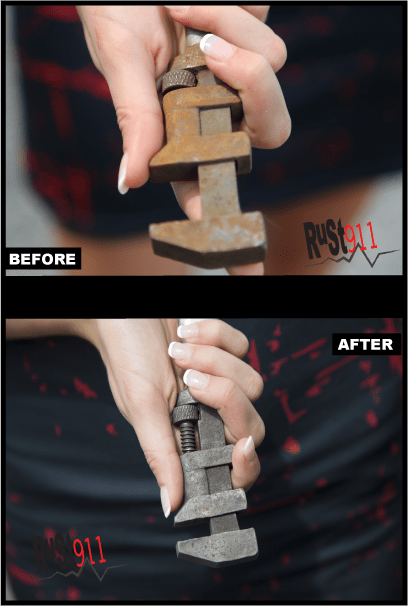

Rusted Metal Tap

Picture of the same tap. The top is severely rusted and was placed into RuSt911 overnight. The bottom picture is the resulting tap completely removed of rust. Even the threads are sharp now. This is a perfect rust removal project that will save your rusted tools.

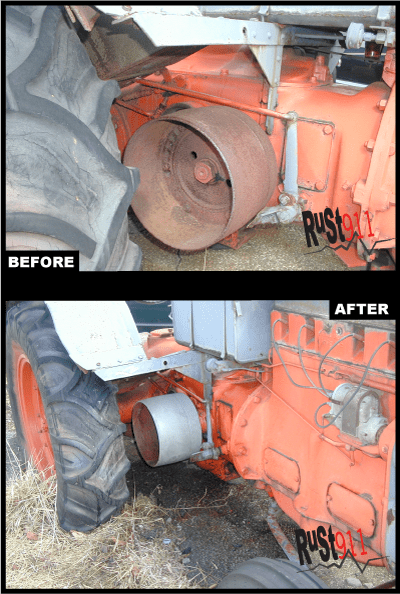

Rusted Tractor Pulley

A severely rusted tractor Power Take Off (PTO) pulley (to the right of the tire). Customer wanted to remove the rust using our rust remover without removing the pulley. A continuous spray system was used so that the part did not have to be removed from the tractor. A hose, garden sprayer, small circulator pump, catch bucket, and a 6'x6' tarp. About a gallon of RuSt911 at 10% was placed in the catch bucket and they turned the pump on. The solution flowed from the bucket and sprayed out on the rusted pulley. The solution dripped onto the tarp and back into the catch basin. It was left on overnight to let the rust remover do its job. The next morning the pumps were stopped and equipment removed. Notice the bright and rust free surface where the fluid was in contact. The rust remover removed the rust and left the paint and rubber tire alone.

Corroded Pot

The bottom was immersed in RuSt911 for 1-hour. The bottom of the pot is brightened. Also notice that the top of the brass pouring spout was brightened ( separately dip in the rust remover). The pot was made of copper and the pouring spout is brass. This rust removal is actually removing the copper oxide

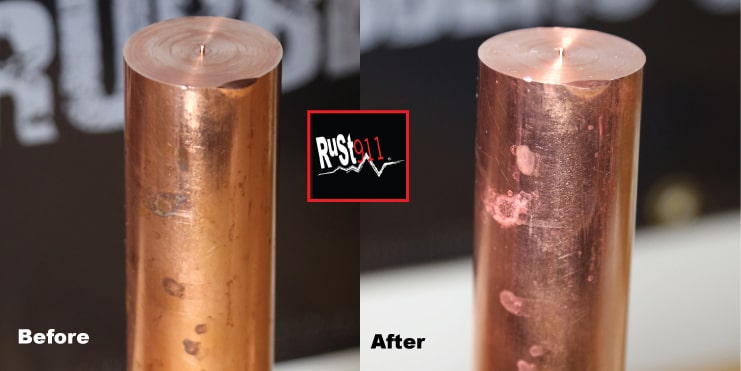

Corroded Copper Pipe

The left side of the pipe was immersed into RuSt911 for 60 seconds and removed. The immersed end is brightened.

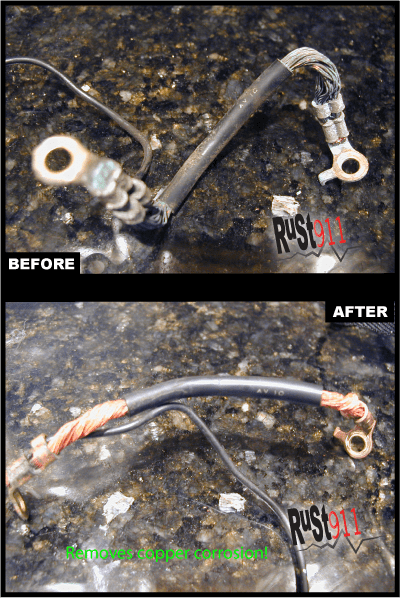

LCorroded Electrical Wire

The wire was immersed into RuSt911 for 5 minutes and removed. The visiable copper wiringhas been brightened. Customer had a very corroded wire that they could not a new one to replace. Top picture shows the corroded wire, note the green near the lugs. The bottom picture shows the wire after being immersed in 10% RuSt911 for about 1/2 hour. Not the green corrosion is gone and the copper returned to its copper color. The customer needed this part to operate their car and the stores were closed. The corrosion was removed in about an hour and the customer was extremely happy to get his car back.

Antique Chain Mail

Customer sent us pics of his old chain mail. There were thousands of impossible to get to areas fo rust, he dunked into our rust remover and overnight turned into this. He was incredibly impressed.

Removes Gun Bluing

Rifle barrel was left in ambient temperature RuSt911 (10%) for 15 minutes. The right side of the barrel is the bluing and the left side is where the bluing has been removed. Another rust remover application.

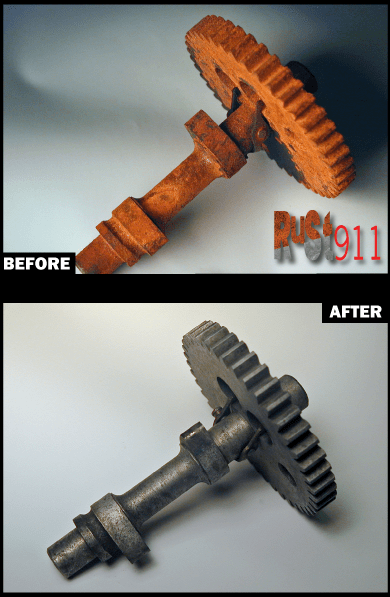

Rusted Cams

Cast iron Cams were rusted until Rust911 Ultra Concentrated Rust Remover helped out.

Antique Brass Fire Extinguisher

We removed the corrosion off from this old fire extinguisher in less than 30 minutes without ruining the painted lettering while retaining its "old " look.

High Purity Copper Bar for Electronics

Customer was complaining about heat treating bars with light corrosion on them were causing problems in their furnaces. After a 5 minute wash, the corrosion was gone and the bars went through the furnace with out further contamination.

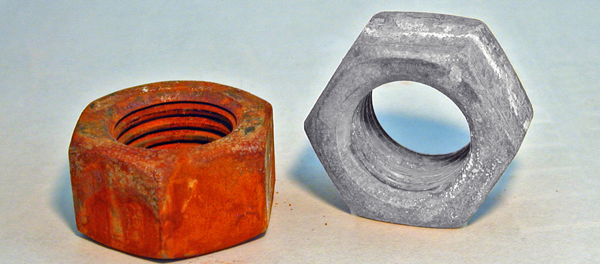

Rusted Nuts

Mixed Rust911 Ultra Concentrate with water at 8 oz./gallon and left in solution for about 2 hours at room temperature, and success

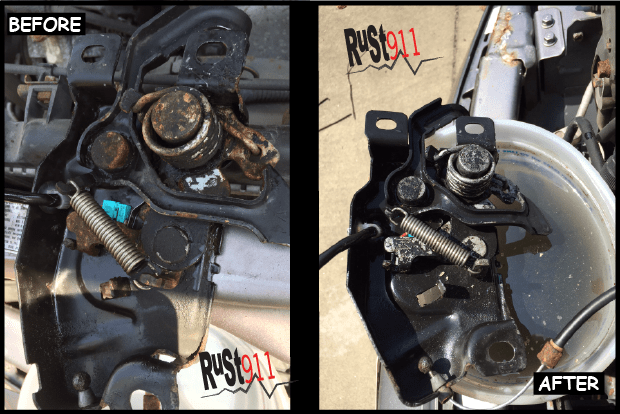

Rusted Honda Hood Latch

This part was not functioning at all and the hood was not easily opened. Customer tried to get another one at local parts store without any luck. They happened to have some Rust911 and tried it. They didn't even have to totally disconnect the latch, after 1 hour, the latch worked like new.

Rusted Tuck Tool

Concrete is corrosive to tools that come into contact with wet cement/concrete. this tool was left in the bed of a truck over the winter and was in bad shape when noticed in the spring. They placed into some diluted ultra concentrate and within 1 hour, the part was as good as shown.

Clutch Plate

We believe this is a clutch plate, not absolutely sure. We immersed 1/2 into solution of mixed rust remover and 1 hour later it appeared as shown..

Rust911 Rust Finder

Rust cant hide from Val

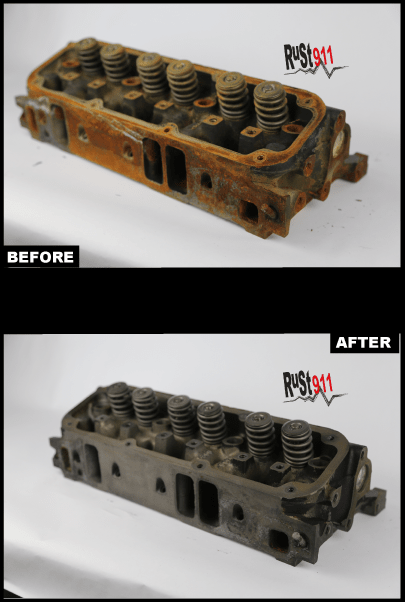

Car Head

Before and After of a Car Head. Note that all the passageways, springs, and all the intricate places the rust remover worked in. No comparison to sand blasting..

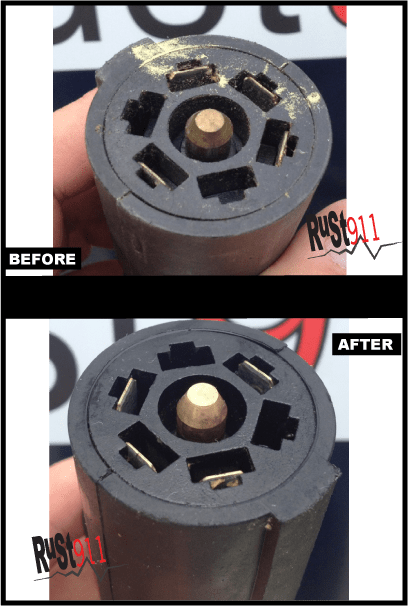

Electrical Plug

Corrosion on copper terminals inside of various plugs like this trailer plug is extremely difficult to remove. Now its not, disconnect electricity and immerse into a plastic water jug, etc. for 15-20 minutes and the corrosion is removed anywhere the liquid sees. Ideal for BMW electrical sockets

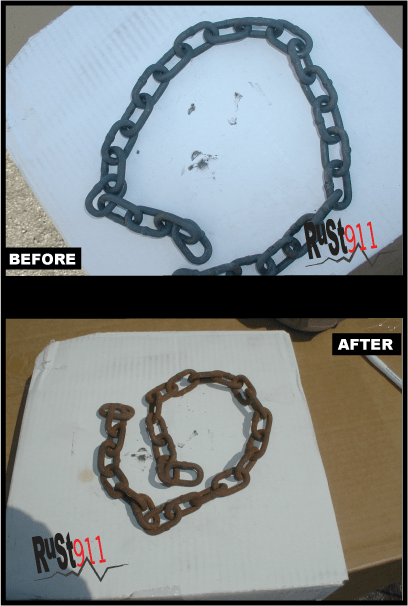

Rusted Chain

Rust911 is perfect for your old rusted chains. Simply immerse into our fluid and let is sit until the rust is completely gone. Leave it in for another hour or so and a protective film builds up and helps from re-rusting. No more getting your hands dirty with rust after handling a rusted chain.

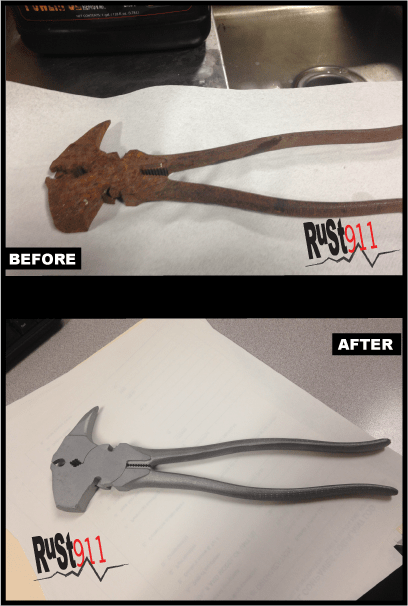

Rusted Tack Puller

Another successful Project by Rust911. Totally frozen before and totally functional now. They look brand new.

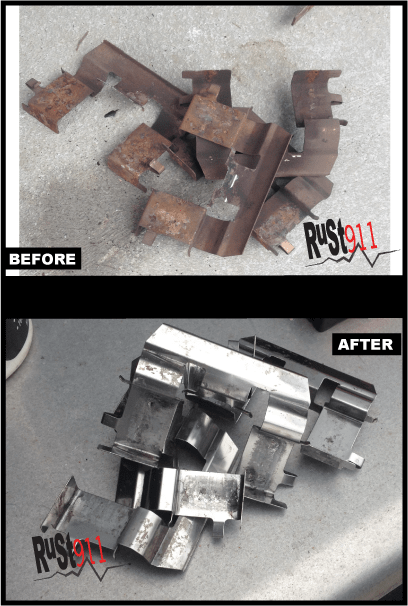

Disc Brake Brackets

These brackets were so rusted they could not be used over again. The new pads did not include the brackets, so immersed them into the Rust911 and now they look amazing.

Rusted Pipe Wrench

The one on the top was immersed in 10% RuSt911 for about 30 minutes and the rust was completely dissolved. Rust911 is perfect for rusted tools and so much more..

Rusted Table Saw

This table saw had mild rusting on it and we used a scotchbrite dipped into our solution and lightly rubbed onto the surface. The rust remover works great with a scotchbrite type pad on light rust.

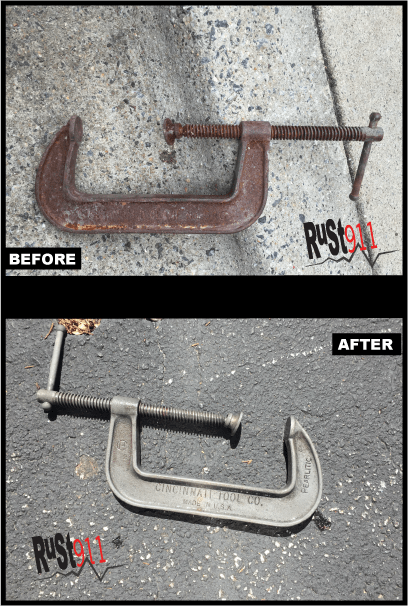

Rusted C-Clamp

Clamp before was un usable and after it is completely functional. This took overnight in diluted rust911 solution.

BBQ Natural Gas Burner

This picture shows the rust melting away from the BBQ grill Burner. the bubble on the burner indicates the reaction and the oxygen being liberated or released during the reaction between our chemical and the iron oxide.

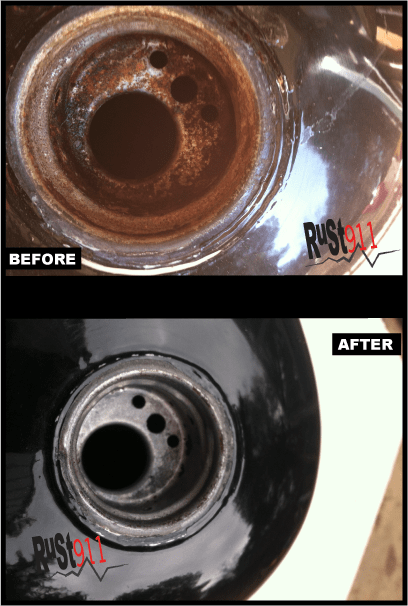

Rusted Motorcycle Gas Tank

Customer sent this into us. They took pictures of the gas tank before and after to show how well it works. The insides of the gas tank looks just as good. Customer gave us an "Awesome Product" as a comment.

Rusted Trailer Hitch

A very common problem with many automotive trailer hitches. The part was immersed in an ambient temperature RuSt911 Industrial Concentrate and left over lunch break. The parts were rinsed off using Metal Kleener 0001 (no longer available, call for suggestions) and sprayed with Metal shield 2009 to protect from flash rusting. notice how much rust removal occurred. Also, it removed rust from the insides of the trailer hitch tube. Awesome rust remover.

Old Rusted Pipe Wrench

This old pipe wrench was from Carlisle Car Show a couple of years ago. It doesn't have any rust now.. .

Cast Iron Pans

We have customers calling about removing rust from cast iron cook-wear and is it safe. Yes it does a great job and since its non-hazardous, non-toxic and biodegradable, it can be used in cook-wear. Always rinse off any remaining residue prior to "seasoning".

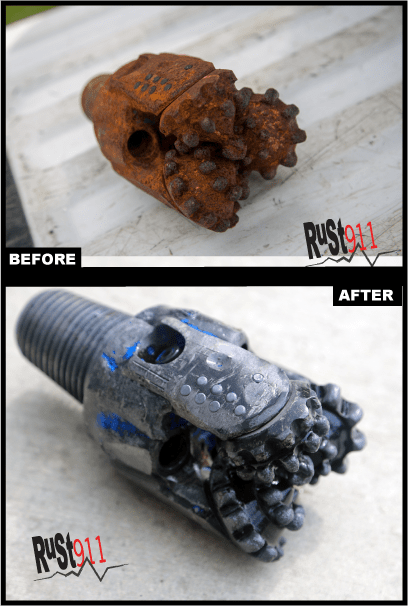

Rusted Gas Well Drill Bit

Here is an intricate drill bit that would be impossible to remove the rust using sandblasting, mechanical abrasion, etc. But, just drop it into a solution of Rust911 and 3-4 hours later. Look at it now. They dont normally remove rust from drill bits for natural gas, but this illustrates the power of Rust911. It even left the paint on it.